| Availability: | |

|---|---|

| Quantity: | |

220DR10AL

Keya

220DR10AL

Overview

MMT Silicon Controlled Series is more reliable and stable by using the unique triggering mode.

It adopts SMT technology and features small size, simple structure and large output power.

To date, it has been applied in a wide range of areas in view of the proven advantages in both

capacity and characteristics of the series.

Applicable areas

MMT series DC motor can be used in machine tools and paper making, presswork, weaving, printing and dyeing,

optical fiber cable equipments, packaging machines, electrician used equipments, food processing machines, rubber producing machines, biology related equipments, PCB printing equipment, experimental equipments, welding and cutting equipments, lightduty equipments, logistics equipments, motor vehicles, medical equipments, and communication equipments, etc.

Product Characteristics:

1. SMT technology is adopted. It features small size and light weight.

2. Applicable to permanent-magnet, separate excitation DC motor.

3. Dual closed loop PI adjustment (Current and Voltage)

4. Large torque for low-speed start-up.

5. It has relatively hard mechanical features. The static-state error ratio is 1%.

6. Wider speed adjusting range

7. Faster dynamic response process

8. Automatic and smooth transition process during acceleration and deceleration.

9. Current setting and current limiting protection (If the preset current value is exceeded, the driver stops output automatically.)

10. Upper range/lower range speed can be adjusted at will.

11. Soft starting/stopping time setting function.

Main Parameters

1. Input Voltage AC: 220V

2. Output Voltage DC: 0-180VDC, 0-220VDC

3. Output CurrentDC: 10A

4. Rated Excitation Voltage/Current DC: 110V/220V 2A

5. Output Voltage Accuracy: ≤1%

6. Given Input Signal: potentiometer control, 0-5v, 0-10v(customed)

7. Ambient Temperature-10ºC~+60ºC

8. Ambient HumidityRelative Humidity≤80RH.Below dew point

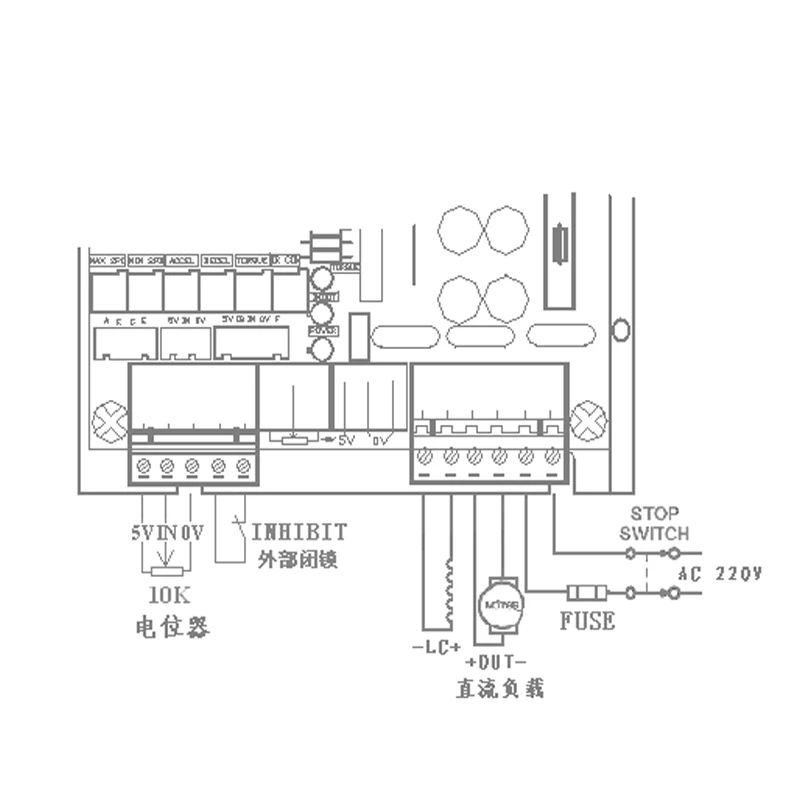

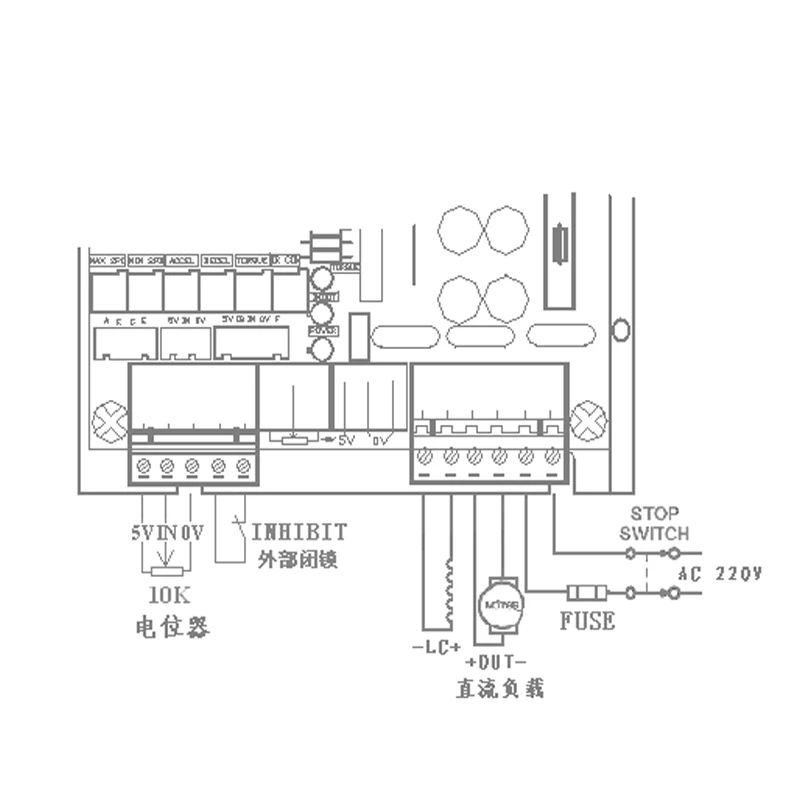

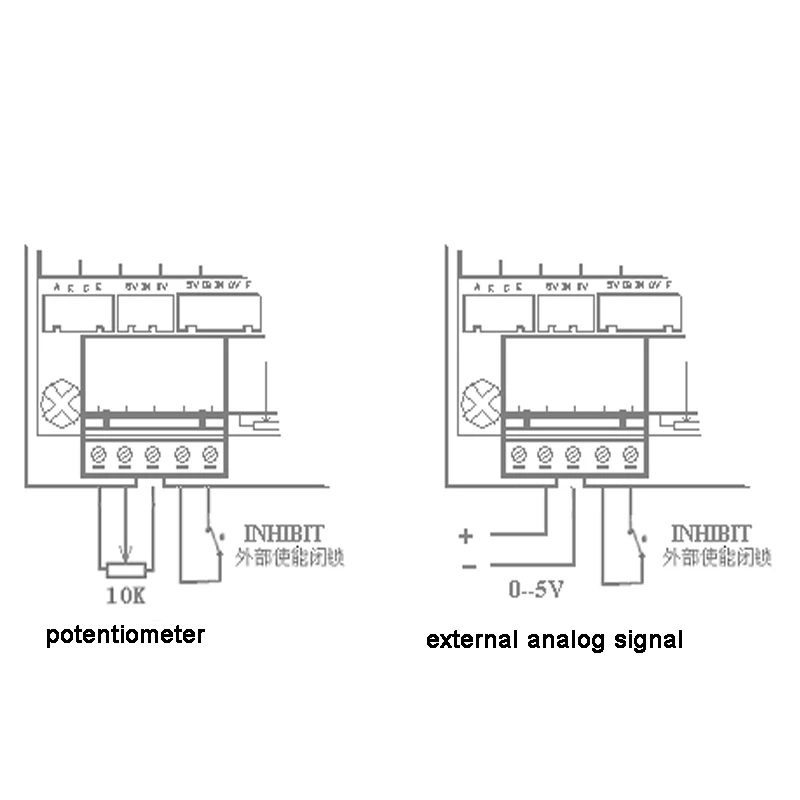

Brushed DC Controller Connect Drawing:

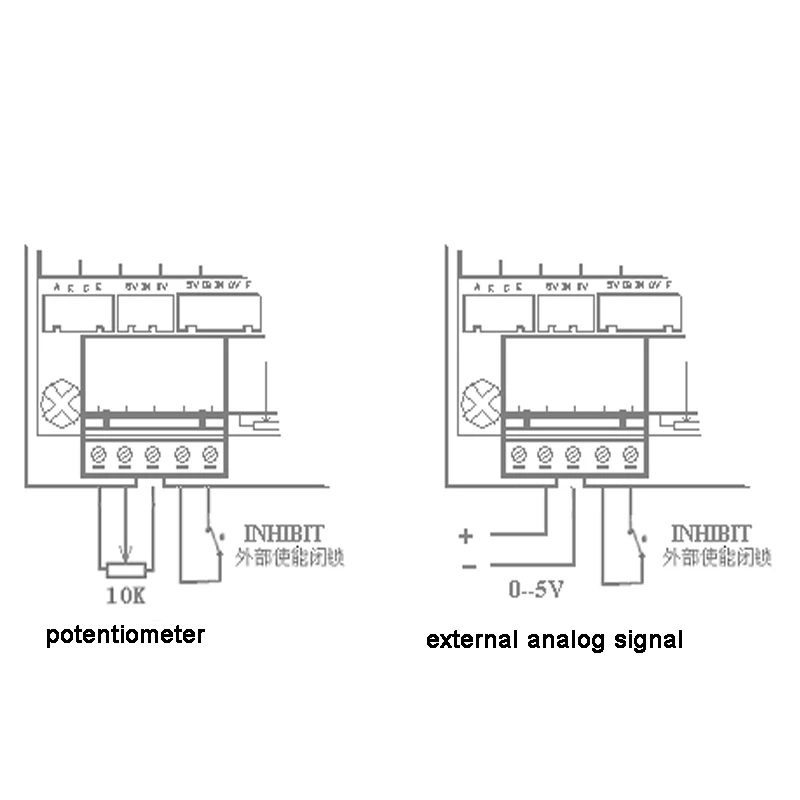

PM Motor DC Controller Control ways:

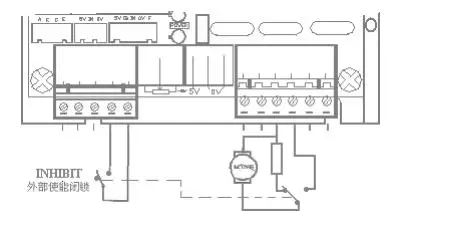

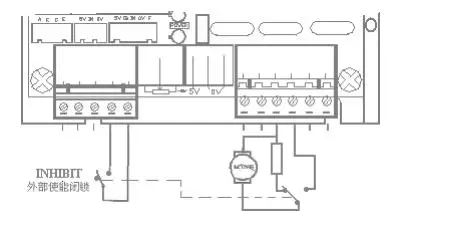

Fast Braking (Energy braking) connection:

Such control mode can achieve good breaking effect.

Selection of break resistance: P (power of break resistance) = actual power of motor×0.8

P (value of break resistance) = rated voltage ÷(rated current×1.2)

Note: When such mode is used for breaking (dynamic breaking), be sure to be used with enable terminal cooperatively, otherwise, drivers may be damaged.

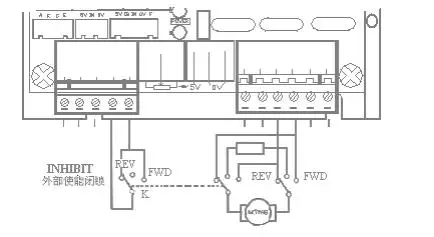

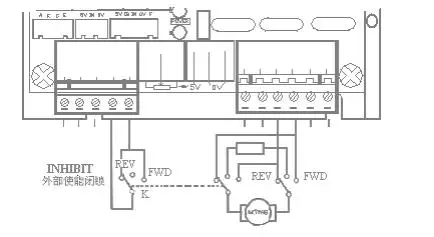

Forward Reverse connection:

Note: When such mode is used for breaking (dynamic breaking), be sure to be used with enable terminal cooperatively, otherwise, drivers may be damaged.

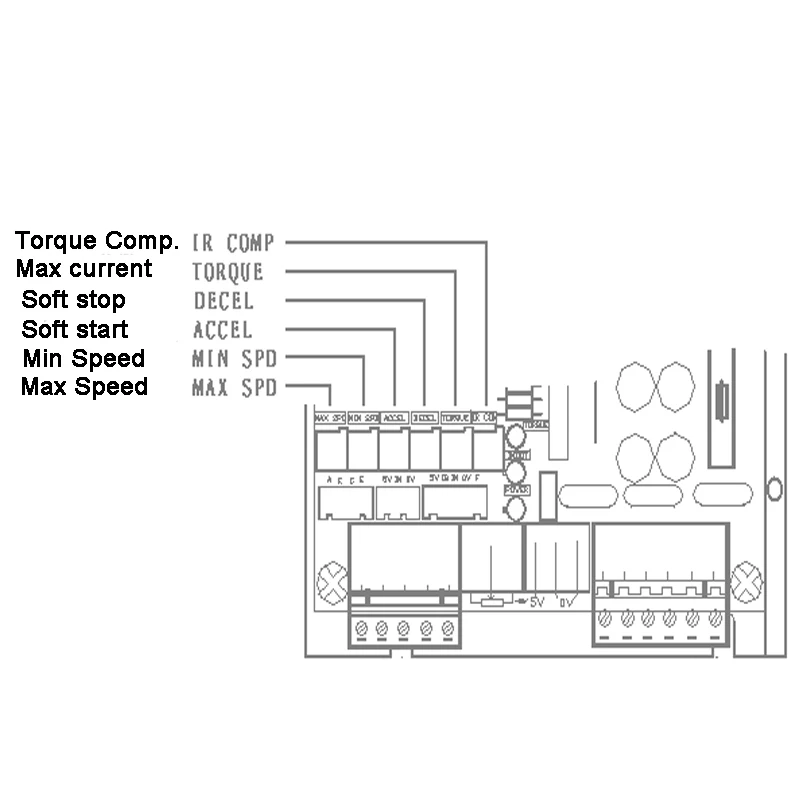

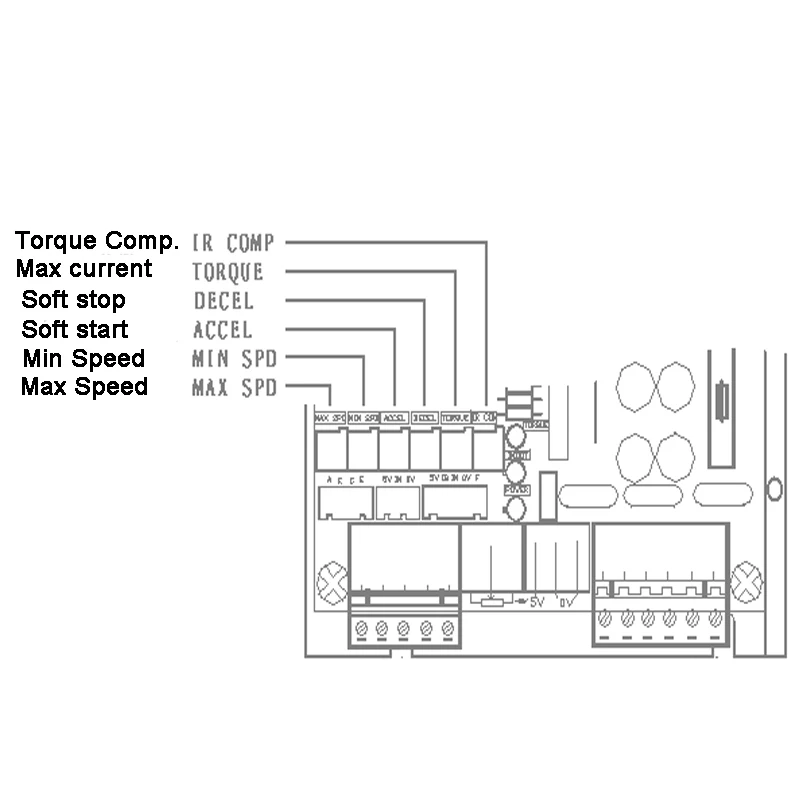

10A DC Controller internal potentiometre:

Note: adjustable angle of all potentiometer is 273°.

1, Maximum speed limit: MAX SPD

Turn the given potentiometer up to maximum value, and then regulate MAX SPD potentiometer to limit the maximum output revolving speed, clockwise rotate to increase output voltage.

2, Minimum speed limit: MIN SPD

Turn the given potentiometer up to minimum value, and then regulate MIN SPD potentiometer to limit the minimum output revolving speed, clockwise rotate to increase output voltage. Note: The speed set by MIN SPD is not controlled by INHIBIT terminal control.

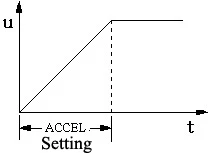

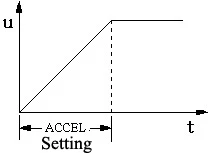

3, Soft starting time regulation: ACCEL

Regulate the ACCEL of such potentiometer can confirm that clockwise time of rising slop rises from initial speed to setting speed (i.e. rise time, setting time can be adjustable within 0.2-20s).

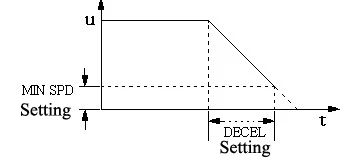

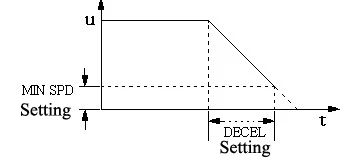

4, Soft stopping time regulation: DECEL

Regulate the DECEL of such potentiometer can confirm that clockwise time of descending slop declines from maximum speed to minimum speed (i.e. fall time, setting time can be adjustable within 0.2-10s).

Note: The minimum actual speed is limited by the MIN SPD potentiometer setting.

5, Current limit regulation: TORQUE

Regulate such potentiometer can limit the maximum output current of driver board, according to motor’s rated current settings selected, maximum output current of driver board shall be 120%-200% of motor’s rated current. Clockwise rotate to increase current.

6, Torque compensation regulation: IR COMP

Regulate IR COMP potentiometer to operate the motor under different loads and keep it revolving speed constant, clockwise rotate to increase torque.

Overview

MMT Silicon Controlled Series is more reliable and stable by using the unique triggering mode.

It adopts SMT technology and features small size, simple structure and large output power.

To date, it has been applied in a wide range of areas in view of the proven advantages in both

capacity and characteristics of the series.

Applicable areas

MMT series DC motor can be used in machine tools and paper making, presswork, weaving, printing and dyeing,

optical fiber cable equipments, packaging machines, electrician used equipments, food processing machines, rubber producing machines, biology related equipments, PCB printing equipment, experimental equipments, welding and cutting equipments, lightduty equipments, logistics equipments, motor vehicles, medical equipments, and communication equipments, etc.

Product Characteristics:

1. SMT technology is adopted. It features small size and light weight.

2. Applicable to permanent-magnet, separate excitation DC motor.

3. Dual closed loop PI adjustment (Current and Voltage)

4. Large torque for low-speed start-up.

5. It has relatively hard mechanical features. The static-state error ratio is 1%.

6. Wider speed adjusting range

7. Faster dynamic response process

8. Automatic and smooth transition process during acceleration and deceleration.

9. Current setting and current limiting protection (If the preset current value is exceeded, the driver stops output automatically.)

10. Upper range/lower range speed can be adjusted at will.

11. Soft starting/stopping time setting function.

Main Parameters

1. Input Voltage AC: 220V

2. Output Voltage DC: 0-180VDC, 0-220VDC

3. Output CurrentDC: 10A

4. Rated Excitation Voltage/Current DC: 110V/220V 2A

5. Output Voltage Accuracy: ≤1%

6. Given Input Signal: potentiometer control, 0-5v, 0-10v(customed)

7. Ambient Temperature-10ºC~+60ºC

8. Ambient HumidityRelative Humidity≤80RH.Below dew point

Brushed DC Controller Connect Drawing:

PM Motor DC Controller Control ways:

Fast Braking (Energy braking) connection:

Such control mode can achieve good breaking effect.

Selection of break resistance: P (power of break resistance) = actual power of motor×0.8

P (value of break resistance) = rated voltage ÷(rated current×1.2)

Note: When such mode is used for breaking (dynamic breaking), be sure to be used with enable terminal cooperatively, otherwise, drivers may be damaged.

Forward Reverse connection:

Note: When such mode is used for breaking (dynamic breaking), be sure to be used with enable terminal cooperatively, otherwise, drivers may be damaged.

10A DC Controller internal potentiometre:

Note: adjustable angle of all potentiometer is 273°.

1, Maximum speed limit: MAX SPD

Turn the given potentiometer up to maximum value, and then regulate MAX SPD potentiometer to limit the maximum output revolving speed, clockwise rotate to increase output voltage.

2, Minimum speed limit: MIN SPD

Turn the given potentiometer up to minimum value, and then regulate MIN SPD potentiometer to limit the minimum output revolving speed, clockwise rotate to increase output voltage. Note: The speed set by MIN SPD is not controlled by INHIBIT terminal control.

3, Soft starting time regulation: ACCEL

Regulate the ACCEL of such potentiometer can confirm that clockwise time of rising slop rises from initial speed to setting speed (i.e. rise time, setting time can be adjustable within 0.2-20s).

4, Soft stopping time regulation: DECEL

Regulate the DECEL of such potentiometer can confirm that clockwise time of descending slop declines from maximum speed to minimum speed (i.e. fall time, setting time can be adjustable within 0.2-10s).

Note: The minimum actual speed is limited by the MIN SPD potentiometer setting.

5, Current limit regulation: TORQUE

Regulate such potentiometer can limit the maximum output current of driver board, according to motor’s rated current settings selected, maximum output current of driver board shall be 120%-200% of motor’s rated current. Clockwise rotate to increase current.

6, Torque compensation regulation: IR COMP

Regulate IR COMP potentiometer to operate the motor under different loads and keep it revolving speed constant, clockwise rotate to increase torque.