| Input Voltage: | |

|---|---|

| Output voltage: | |

| Max current: | |

| Control signal: | |

| Availability: | |

| Quantity: | |

115/230DR10AL-02

Keya

115/230DR10AL-02

This dc motor controller is a kind of speed governing product developed and produced by adopting past successful experience and combining modern advanced technology.

This180v dc motor controller have met international standard requirements and are sold to many countries. This brushed dc motor speed control adopts thyristor chopping control principle and uses independent trigger mode. Even there is no velocity feedback, high speed ratio can be achieved to make it more accurate and reliable.

Excellent performance, reliable quality and high cost performance make this dc controller a strong performer in DC motor driver field and it was widely used in plastic machinery, food machinery, cable equipment, machining, paper printing, testing equipment, laboratory equipment and mixing equipment, etc.

1. SMT technology, small size

2. Good following features, rapid respond speed

3. Wide speed ratio, strong mechanical features

4. Applicable to permanent magnet motor, brushed dc motor

5. Double closed-loop PI regulation (Voltage, current)

6. Current setting and current-limiting protection (continuous operation setting current)

7. Large torque with low speed

8. Over-current protection function

9. Quick stop function

10. Arbitrary setting of upper and lower speed

11. Soft start, soft stop setting function

12. Selection of speed mode, torque mode

13. Normally open, close selection of enable signal

14. Selection of input, output voltage switch

15. Driver speed governing controlled by standard signal input 0-5V or 10K potentiometer

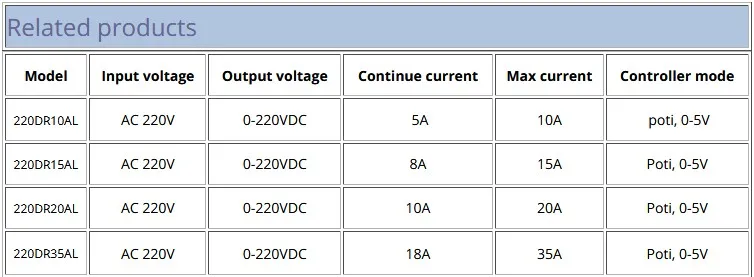

| Specification for 115/230DR10AL-02 | |

| Input voltage range | 220VAC (if you need 110VAC, please adjsut the input switch) |

| Max output current | 10A |

| Output voltage | 0-90V 0-110V 0-160V 0-180V 0-220V (The standard model with output DC180V or DC220V, and you can adjust the output voltage by yourself, when you need any help, please contact us, we will be happy to assist. Email: sales@jnky.com) |

| Operating mode | Speed mode, Torque mode |

| Control ways | Potentiometer, external analog signal 0-5V (if you need 0-10V, kindly adivse) |

| Protection | Abnormalitise like over current, overheating, over voltage, less voltage and short circuit will start the protection function. |

| Temperature protection | When the temperature is 70, the controller will reduce output by overheating protection and stop output. |

| Working Temperature | -10 -- +60 |

| Ambient humidity | Relative humidity less than 80RH |

| Size | L*W*H = 116*103*48 mm |

| Weight | 500g |

| Matched motor | DC 90v 110v 200w - 600w and 180v 220v 400w - 1200w PMDC Motor, brushed dc motor |

0-5v 0-10v analog signal control switchable 110v 220v ac input 90v 180v dc motor speed controller 10A for welding positoner

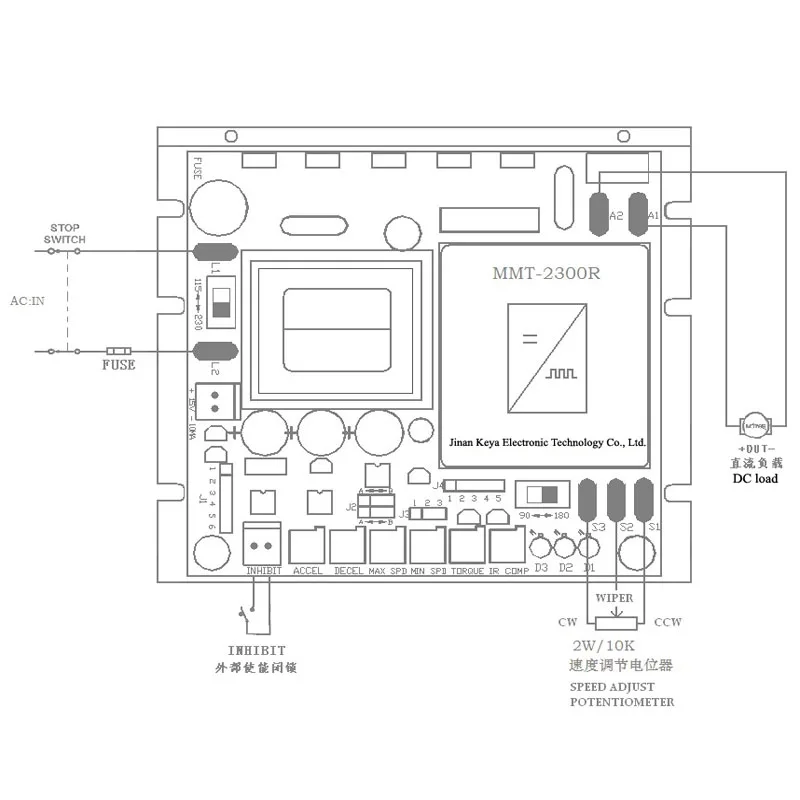

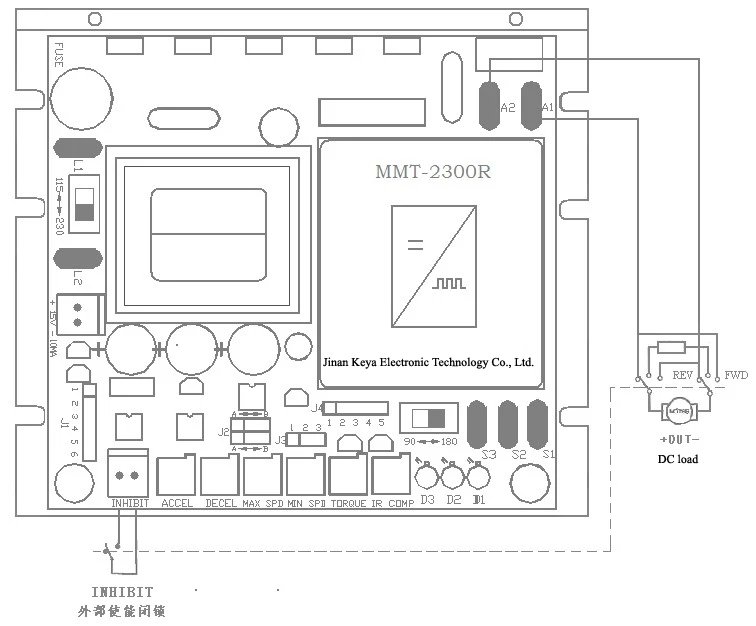

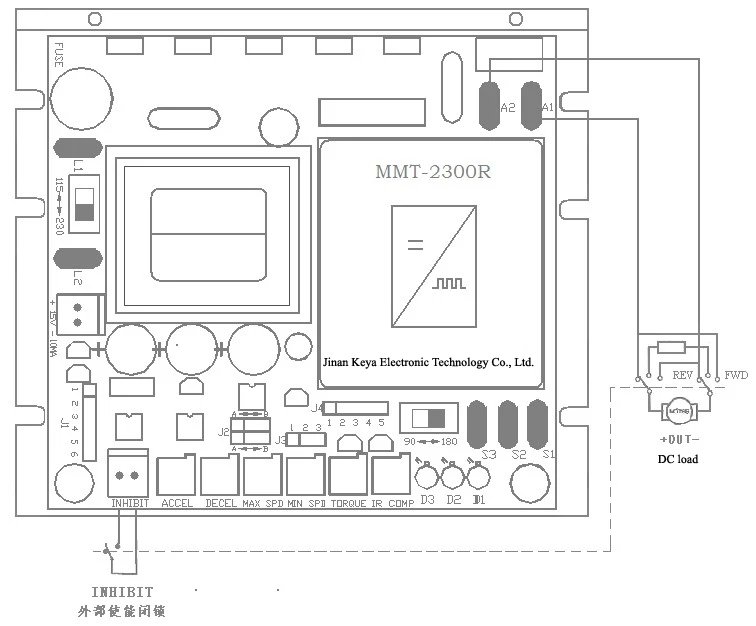

General connect drawing:

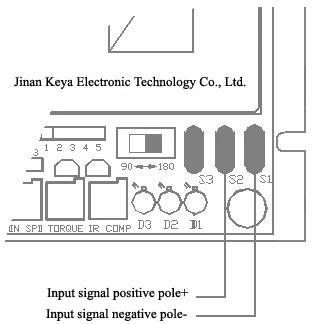

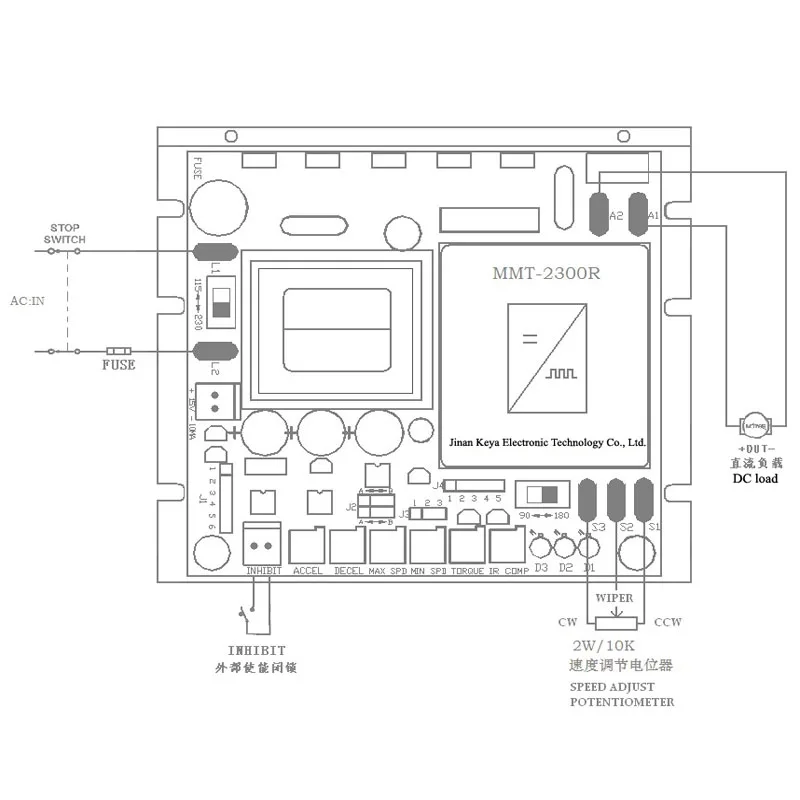

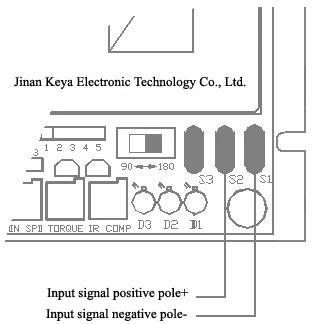

You also can control the speed by 0-5V or 0-10V analog signal:

Notice: the standard model with 0-5V control, if you need 0-10V, kindly leave the message when place the order

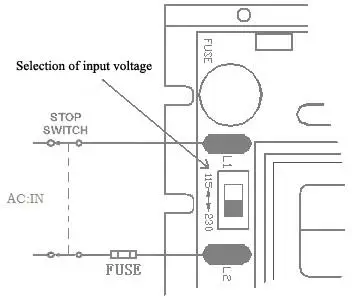

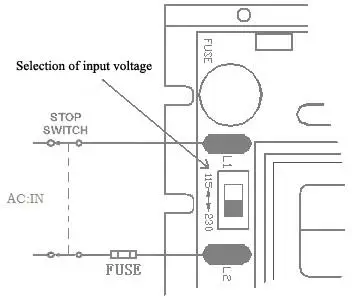

Input Voltage Switch

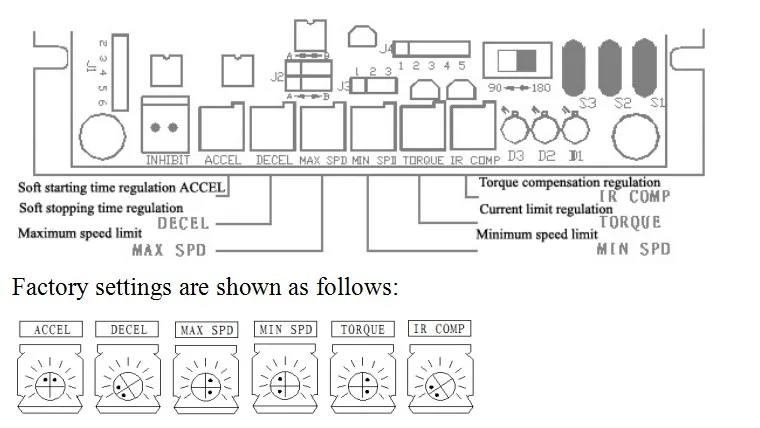

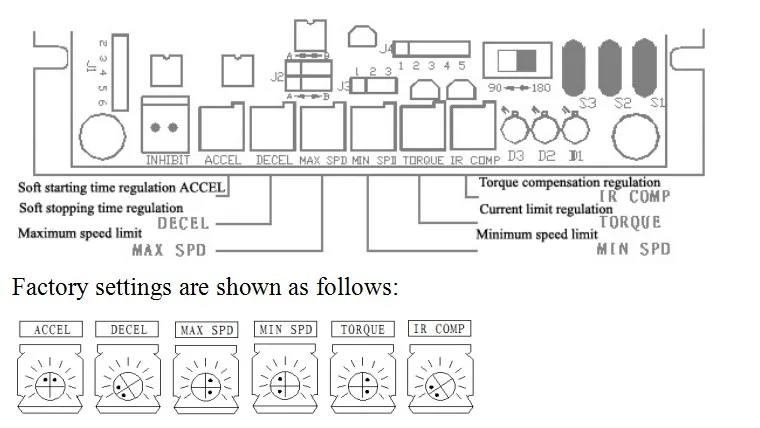

Internal potentiometer description

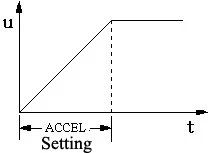

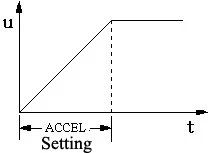

1. Soft starting time regulation: ACCEL

Regulate the ACCEL of such potentiometer can confirm that clockwise time of rising slop rises from initial speed to setting speed (i.e. rise time, setting time can be adjustable within 0.2-20s).

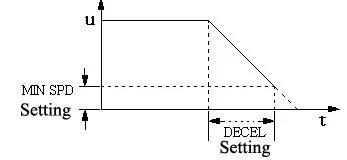

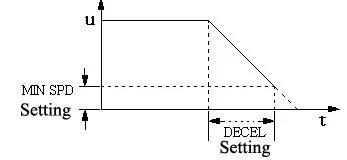

2. Soft stopping time regulation: DECEL

Regulate the DECEL of such potentiometer can confirm that clockwise time of descending slop declines from maximum speed to minimum speed (i.e. fall time, setting time can be adjustable within 0.2-10s).

3. Maximum speed limit: MAX SPD

Turn the given potentiometer up to maximum value, and then regulate MAX SPD potentiometer to limit the maximum output revolving speed, clockwise rotate to increase output voltage.

4. Minimum speed limit: MIN SPD

Turn the given potentiometer up to minimum value, and then regulate MIN SPD potentiometer to limit the minimum output revolving speed, clockwise rotate to increase output voltage.

5. Current limit regulation: TORQUE

Regulate such potentiometer can limit the maximum output current of driver board, according to motor’s rated current settings selected, maximum output current of driver board shall be 120%-200% of motor’s rated current. Clockwise rotate to increase current.

6. Torque compensation regulation: IR COMP

Regulate IR COMP potentiometer to operate the motor under different loads and keep it revolving speed constant, clockwise rotate to increase torque.

How control the motor Reverse and Forward

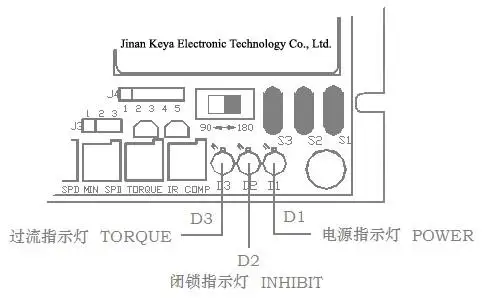

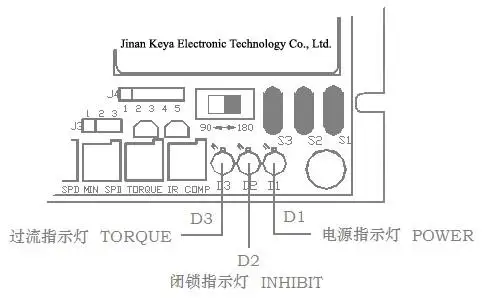

Indicator discription

This dc motor controller is a kind of speed governing product developed and produced by adopting past successful experience and combining modern advanced technology.

This180v dc motor controller have met international standard requirements and are sold to many countries. This brushed dc motor speed control adopts thyristor chopping control principle and uses independent trigger mode. Even there is no velocity feedback, high speed ratio can be achieved to make it more accurate and reliable.

Excellent performance, reliable quality and high cost performance make this dc controller a strong performer in DC motor driver field and it was widely used in plastic machinery, food machinery, cable equipment, machining, paper printing, testing equipment, laboratory equipment and mixing equipment, etc.

1. SMT technology, small size

2. Good following features, rapid respond speed

3. Wide speed ratio, strong mechanical features

4. Applicable to permanent magnet motor, brushed dc motor

5. Double closed-loop PI regulation (Voltage, current)

6. Current setting and current-limiting protection (continuous operation setting current)

7. Large torque with low speed

8. Over-current protection function

9. Quick stop function

10. Arbitrary setting of upper and lower speed

11. Soft start, soft stop setting function

12. Selection of speed mode, torque mode

13. Normally open, close selection of enable signal

14. Selection of input, output voltage switch

15. Driver speed governing controlled by standard signal input 0-5V or 10K potentiometer

| Specification for 115/230DR10AL-02 | |

| Input voltage range | 220VAC (if you need 110VAC, please adjsut the input switch) |

| Max output current | 10A |

| Output voltage | 0-90V 0-110V 0-160V 0-180V 0-220V (The standard model with output DC180V or DC220V, and you can adjust the output voltage by yourself, when you need any help, please contact us, we will be happy to assist. Email: sales@jnky.com) |

| Operating mode | Speed mode, Torque mode |

| Control ways | Potentiometer, external analog signal 0-5V (if you need 0-10V, kindly adivse) |

| Protection | Abnormalitise like over current, overheating, over voltage, less voltage and short circuit will start the protection function. |

| Temperature protection | When the temperature is 70, the controller will reduce output by overheating protection and stop output. |

| Working Temperature | -10 -- +60 |

| Ambient humidity | Relative humidity less than 80RH |

| Size | L*W*H = 116*103*48 mm |

| Weight | 500g |

| Matched motor | DC 90v 110v 200w - 600w and 180v 220v 400w - 1200w PMDC Motor, brushed dc motor |

0-5v 0-10v analog signal control switchable 110v 220v ac input 90v 180v dc motor speed controller 10A for welding positoner

General connect drawing:

You also can control the speed by 0-5V or 0-10V analog signal:

Notice: the standard model with 0-5V control, if you need 0-10V, kindly leave the message when place the order

Input Voltage Switch

Internal potentiometer description

1. Soft starting time regulation: ACCEL

Regulate the ACCEL of such potentiometer can confirm that clockwise time of rising slop rises from initial speed to setting speed (i.e. rise time, setting time can be adjustable within 0.2-20s).

2. Soft stopping time regulation: DECEL

Regulate the DECEL of such potentiometer can confirm that clockwise time of descending slop declines from maximum speed to minimum speed (i.e. fall time, setting time can be adjustable within 0.2-10s).

3. Maximum speed limit: MAX SPD

Turn the given potentiometer up to maximum value, and then regulate MAX SPD potentiometer to limit the maximum output revolving speed, clockwise rotate to increase output voltage.

4. Minimum speed limit: MIN SPD

Turn the given potentiometer up to minimum value, and then regulate MIN SPD potentiometer to limit the minimum output revolving speed, clockwise rotate to increase output voltage.

5. Current limit regulation: TORQUE

Regulate such potentiometer can limit the maximum output current of driver board, according to motor’s rated current settings selected, maximum output current of driver board shall be 120%-200% of motor’s rated current. Clockwise rotate to increase current.

6. Torque compensation regulation: IR COMP

Regulate IR COMP potentiometer to operate the motor under different loads and keep it revolving speed constant, clockwise rotate to increase torque.

How control the motor Reverse and Forward

Indicator discription