| Availability: | |

|---|---|

| Quantity: | |

220DR20AL

Keya

220DR20AL

180V 20A DC Motor Controller 220DR20AL

MMT-220DR serial DC motor drive adopts SCR chopper, which has unique trigger mode, thus

making it more accurate and reliable. The drive is the update speed regulation product which

develops and produces in combination with the international standard requirements and absorbs

advanced technology experience. The drive has high performance-cost ratio because of its

excellent performance and reliable quality. (It can reach high speed ratio even when at non-speed

feedback) It is above average in DC motor drive field. Currently, the serial products have been

exported to many countries and widely used in fields of domestic plastics machinery, food

machinery, cable equipment, mechanical processing, papermaking, printing, experimental

equipment, laboratory equipment, mixing equipment and so on.

Product Features

1. SMT technology Small volume

2. Applicable to permanent-magnet, separate excitation DC motor and DC torque motor

3. Dual closed loop PI adjustment (Current and Voltage)

4. Current setting and current limiting protection

5. The speed control mode and expansive force control mode are selectable.

6. Large torque for low-speed start-up.

7. Quick stop function

8. Upper limit and Low limit can be set up to different need

9. ACCEL and DECEL function

10. Standard signal interface 0-5V or 10K potentiometer

11. Can realize remote start and stop, Fine following performance; immediate dynamic response

12. A wide speed-regulating range (0 - max).

13. Strong mechanical features, static voltage error 1%

14. A rapid dynamic response process.( adjustable)

15. Automatic and smooth transition process during acceleration or deceleration.

16. Good excavator features, can automatically overload current limit on the current settings.

17. High reliability, compact structure and highly cost-effective.

Main Parameters

1. AC Input Voltage : 110V / 220V±10﹪。

2. AC Frequency (Hz):-50/60

3. Output voltage DC: 0~90V 0-110V 0-160V 0-180V 0-220V (Can be set)

3. Rated Armature current: ﹙DC100V or 200V﹚ 3A

4. Rated output current: 20A

5. Speed adjust ratio: 1:100

6. Output voltage accuracy: ≤0.1﹪

7. Ambient temperature :10℃- +60℃ :

8. Ambient Humidity: Relative Humidity≤80RH.( Below dew point)

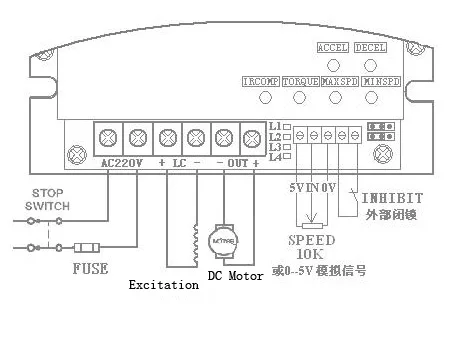

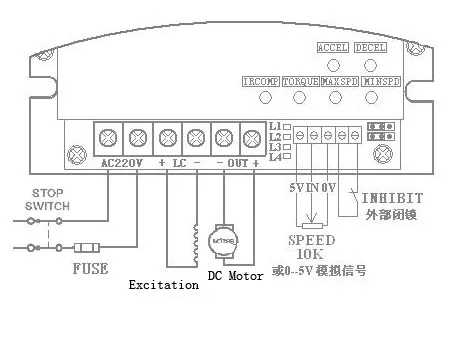

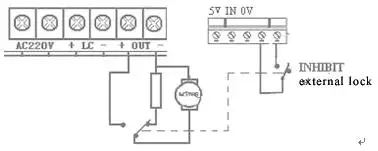

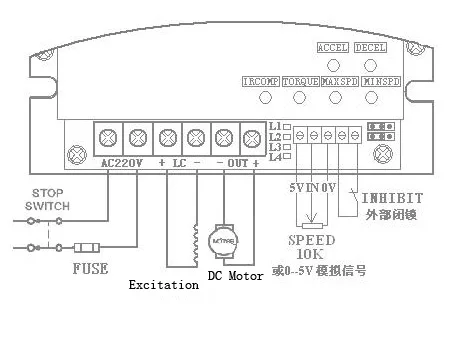

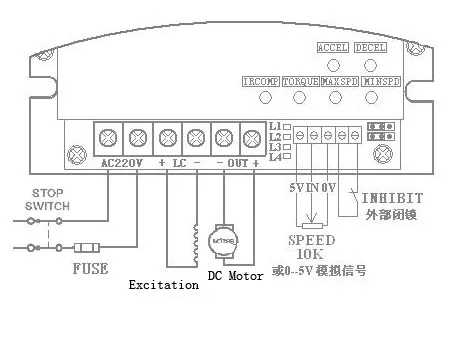

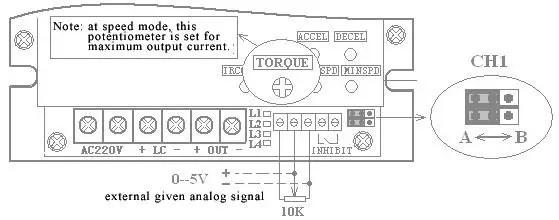

220V Brushed DC Controller Connect Drawing:

Enable control: INHIBIT

Control the motor Start and Stop

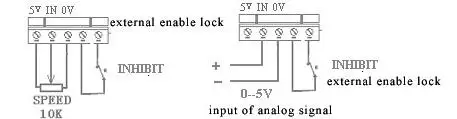

180V dc motor speed control signal:

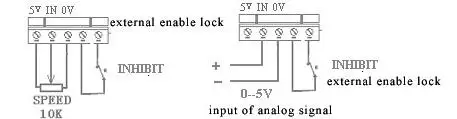

1. The serial products adopt the full isolation mode and the external given signal can connect directly with the signal input terminal of drive.

External potentiometers and analog signals for a given amount of signal for a given connection method

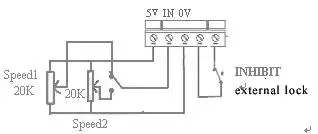

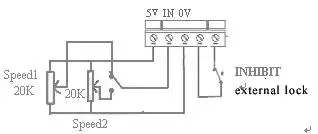

2. Several potentiometer series / parallel usag

Means a potentiometer in parallel: This control mode enables two or more to adjust, use is simple and reliable. However, the total potentiometer resistance should be equal to 10K. (Potentiometer connection is best to use shielded line)

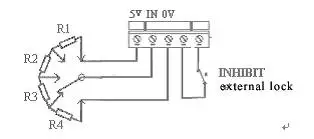

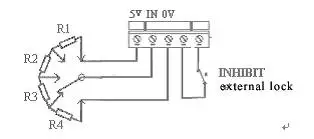

3. Resistors in series connection

This control method can achieve multi-stall speed control, used in a variety of occasions. However, the total resistance of resistors in series shown in the picture be equal to 10K.

110V 220V dc motor controller with excitation Internal potentiometer definition:

Notice: Clock wise rotation to increase, anticlockwise rotation to decrease.

1. MAX SPD

Adjust the MAX SPD potentiometer to limit the motor maximum speed. that means you can adjust the controller output voltage via this potentiometer. clockwise the potentiometer to increase the output voltage.

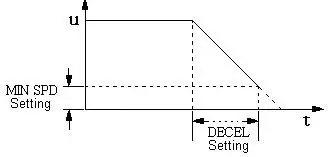

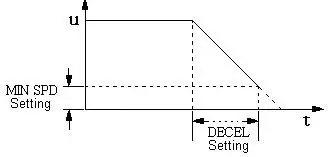

2. MIN SPD

Adjust the MIN SPD potentiometer to limit the motor minimum speed.

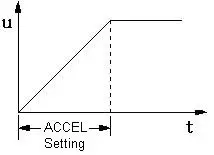

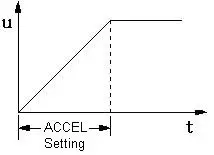

3. ACCEL Soft-start time adjustment

This adjustment of potentiometers ACCEL can make sure motor’s rising slope from the initial velocity up to the highest velocity (that is rising time, set time adjustable during 0-20 seconds).

4. Soft-stop time adjustment (The interior has been fixed): DECEL

Adjustment of potentiometers DECEL can make sure motor’s decline slope when speed dropped from the highest to the lowest (that is falling time, set time adjustable during 0-20 seconds).

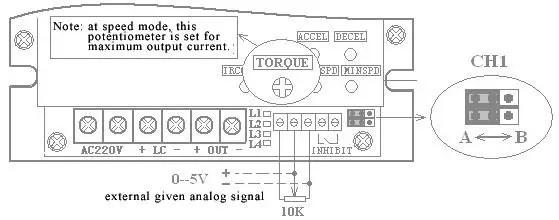

5. Current limit adjustment: TORQUE (when Under speed mode condition ) Adjustment of the potentiometer can restrict drive plate to a maximum output current.

Based on your selection of the motor’s rated current, we can use this potentiometer to adjust driver output current to match the motor rated current.

Note: In the choice of driver, the driver’s maximum output current should be 120% to 200% of motor rated current.

6. Torque compensation adjustments: IR COMP

Adjust this potentiometer can keep a constant rotation speed when motor works in different load.

Speed mode and Tension mode selection:

1. Selection of speed mode:

2. Selection of tension mode:

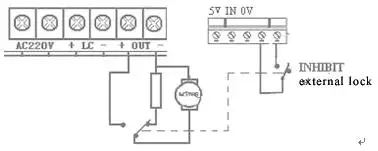

Rapid braking (dynamic braking) of the connection:

Note: When using this method when braking (dynamic braking) Please be sure to enable the port used in conjunction with, otherwise it will damage the bruhsed dc controller.

This control method can obtain good braking effect. Braking resistor selection:

RW (braking resistor power) = motor actual power X (0.6-0.8)

R (braking resistor resistance) = Rated Voltage / (rated current X 1.2)

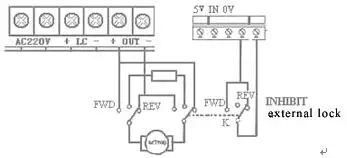

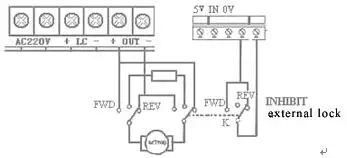

Forward / Rreverse:

Note: When using this method when braking (dynamic braking) Please be sure to enable the port used in conjunction with, otherwise it will damage the dc controller.

180V 20A DC Motor Controller 220DR20AL

MMT-220DR serial DC motor drive adopts SCR chopper, which has unique trigger mode, thus

making it more accurate and reliable. The drive is the update speed regulation product which

develops and produces in combination with the international standard requirements and absorbs

advanced technology experience. The drive has high performance-cost ratio because of its

excellent performance and reliable quality. (It can reach high speed ratio even when at non-speed

feedback) It is above average in DC motor drive field. Currently, the serial products have been

exported to many countries and widely used in fields of domestic plastics machinery, food

machinery, cable equipment, mechanical processing, papermaking, printing, experimental

equipment, laboratory equipment, mixing equipment and so on.

Product Features

1. SMT technology Small volume

2. Applicable to permanent-magnet, separate excitation DC motor and DC torque motor

3. Dual closed loop PI adjustment (Current and Voltage)

4. Current setting and current limiting protection

5. The speed control mode and expansive force control mode are selectable.

6. Large torque for low-speed start-up.

7. Quick stop function

8. Upper limit and Low limit can be set up to different need

9. ACCEL and DECEL function

10. Standard signal interface 0-5V or 10K potentiometer

11. Can realize remote start and stop, Fine following performance; immediate dynamic response

12. A wide speed-regulating range (0 - max).

13. Strong mechanical features, static voltage error 1%

14. A rapid dynamic response process.( adjustable)

15. Automatic and smooth transition process during acceleration or deceleration.

16. Good excavator features, can automatically overload current limit on the current settings.

17. High reliability, compact structure and highly cost-effective.

Main Parameters

1. AC Input Voltage : 110V / 220V±10﹪。

2. AC Frequency (Hz):-50/60

3. Output voltage DC: 0~90V 0-110V 0-160V 0-180V 0-220V (Can be set)

3. Rated Armature current: ﹙DC100V or 200V﹚ 3A

4. Rated output current: 20A

5. Speed adjust ratio: 1:100

6. Output voltage accuracy: ≤0.1﹪

7. Ambient temperature :10℃- +60℃ :

8. Ambient Humidity: Relative Humidity≤80RH.( Below dew point)

220V Brushed DC Controller Connect Drawing:

Enable control: INHIBIT

Control the motor Start and Stop

180V dc motor speed control signal:

1. The serial products adopt the full isolation mode and the external given signal can connect directly with the signal input terminal of drive.

External potentiometers and analog signals for a given amount of signal for a given connection method

2. Several potentiometer series / parallel usag

Means a potentiometer in parallel: This control mode enables two or more to adjust, use is simple and reliable. However, the total potentiometer resistance should be equal to 10K. (Potentiometer connection is best to use shielded line)

3. Resistors in series connection

This control method can achieve multi-stall speed control, used in a variety of occasions. However, the total resistance of resistors in series shown in the picture be equal to 10K.

110V 220V dc motor controller with excitation Internal potentiometer definition:

Notice: Clock wise rotation to increase, anticlockwise rotation to decrease.

1. MAX SPD

Adjust the MAX SPD potentiometer to limit the motor maximum speed. that means you can adjust the controller output voltage via this potentiometer. clockwise the potentiometer to increase the output voltage.

2. MIN SPD

Adjust the MIN SPD potentiometer to limit the motor minimum speed.

3. ACCEL Soft-start time adjustment

This adjustment of potentiometers ACCEL can make sure motor’s rising slope from the initial velocity up to the highest velocity (that is rising time, set time adjustable during 0-20 seconds).

4. Soft-stop time adjustment (The interior has been fixed): DECEL

Adjustment of potentiometers DECEL can make sure motor’s decline slope when speed dropped from the highest to the lowest (that is falling time, set time adjustable during 0-20 seconds).

5. Current limit adjustment: TORQUE (when Under speed mode condition ) Adjustment of the potentiometer can restrict drive plate to a maximum output current.

Based on your selection of the motor’s rated current, we can use this potentiometer to adjust driver output current to match the motor rated current.

Note: In the choice of driver, the driver’s maximum output current should be 120% to 200% of motor rated current.

6. Torque compensation adjustments: IR COMP

Adjust this potentiometer can keep a constant rotation speed when motor works in different load.

Speed mode and Tension mode selection:

1. Selection of speed mode:

2. Selection of tension mode:

Rapid braking (dynamic braking) of the connection:

Note: When using this method when braking (dynamic braking) Please be sure to enable the port used in conjunction with, otherwise it will damage the bruhsed dc controller.

This control method can obtain good braking effect. Braking resistor selection:

RW (braking resistor power) = motor actual power X (0.6-0.8)

R (braking resistor resistance) = Rated Voltage / (rated current X 1.2)

Forward / Rreverse:

Note: When using this method when braking (dynamic braking) Please be sure to enable the port used in conjunction with, otherwise it will damage the dc controller.