| Availability: | |

|---|---|

| Quantity: | |

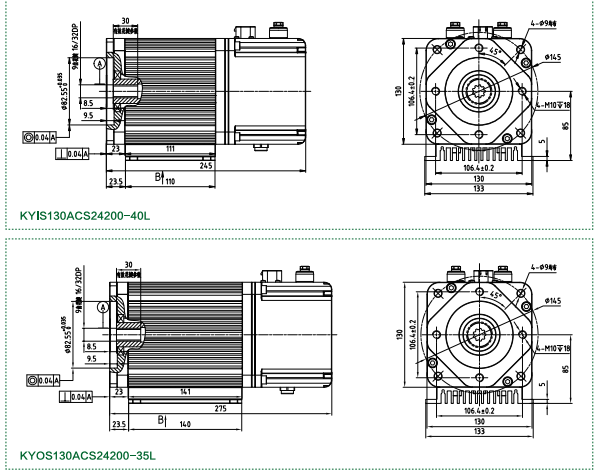

KYIS130AS24200-40L

Keya

| Product name | KYIS130ACS24200-40L |

| Project name | Parameters |

| Rated voltage | 24V±10% |

| Limited supply voltage | 18-32V |

| Motor rated power | 3500W |

| Rated current | 110A±5% |

| Rated speed | 3000RPM |

| Rated torque | 9.55N·m |

| Maximum speed | 4000RPM (rated voltage) |

| Instantaneous maximum current | 200A±5% |

| Instantaneous maximum torque | 16 N·m |

| Number of poles | 10 |

| Feedback signal | Encoder |

| Applicable motor | 1500-3500W |

| Ambient temperature | -25-+50℃ |

| Insulation performance | Input and output to housing DC600V, leakage current 0.07mA; insulation resistance 20MΩ or more |

| Connector | TE 776286-1 (control end connector) |

| Three-proof requirements | Meet the three-proof requirements (dustproof, moisture-proof, salt spray-proof) |

| Relative humidity | 0% ~ 90%RH , with condensation (25°C) |

| Vibration requirements | Frequency 5HZ-25HZ, amplitude 3mm, 0.09g; 25HZ-200HZ, amplitude 1.47mm, 116g |

| Protection level | IP67 |

| Cooling method | Natural cooling |

| Weight | 9.8kg |

The system has high efficiency, with an overall maximum efficiency of 93%.

The starting current is small and the torque is large.

Integrated design, compact size, small footprint, easy installation

FOC vector control, high-precision encoder feedback, stable pressure output.

The whole machine is maintenance-free, and no carbon brushes need to be replaced.

The driver and motor have built-in independent temperature alarm thresholds and protection devices.

It can meet the use of harsh working conditions. In addition to the motor output shaft, the protection level is as high as IP67

Equipped with a power contactor pull-in abnormal alarm device.

The output shaft method is optional: (optical shaft flat key,

internal tooth spline and external tooth spline).

Designed by a professional R&D team, providing technical support

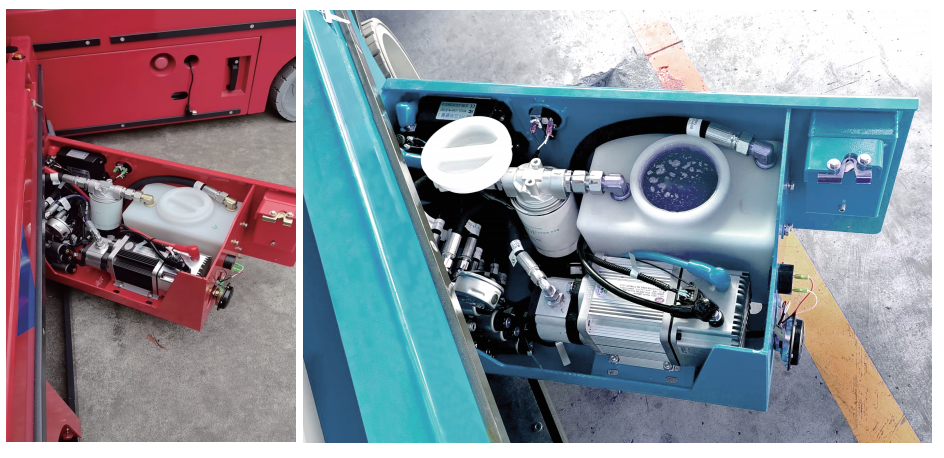

Keya's Integrated Servo Motor can be used in scissor lift work platforms; boom-type aerial vehicles; DC power supply variable frequency hydraulic power units and engineering machinery electric assisted steering; special vehicle travel drives, etc.

This is a picture showing Keya's servo integrated machine installed on Scissor Lift Platforms,

We have reached cooperation with aerial work vehicle companies in many regions such as Europe, South America, Asia, etc. If you are looking for servo system solutions for projects such as scissor lift work platforms; boom-type aerial vehicles; DC power supply variable frequency hydraulic power units and engineering machinery electric assisted steering; special vehicle travel drives, etc., you can contact us for the latest quotation.

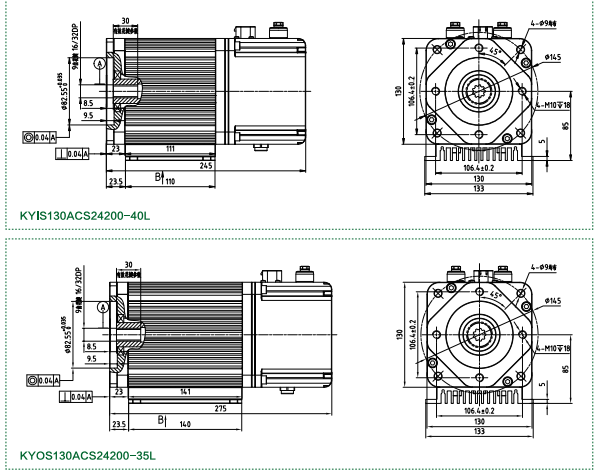

| Product name | KYIS130ACS24200-40L |

| Project name | Parameters |

| Rated voltage | 24V±10% |

| Limited supply voltage | 18-32V |

| Motor rated power | 3500W |

| Rated current | 110A±5% |

| Rated speed | 3000RPM |

| Rated torque | 9.55N·m |

| Maximum speed | 4000RPM (rated voltage) |

| Instantaneous maximum current | 200A±5% |

| Instantaneous maximum torque | 16 N·m |

| Number of poles | 10 |

| Feedback signal | Encoder |

| Applicable motor | 1500-3500W |

| Ambient temperature | -25-+50℃ |

| Insulation performance | Input and output to housing DC600V, leakage current 0.07mA; insulation resistance 20MΩ or more |

| Connector | TE 776286-1 (control end connector) |

| Three-proof requirements | Meet the three-proof requirements (dustproof, moisture-proof, salt spray-proof) |

| Relative humidity | 0% ~ 90%RH , with condensation (25°C) |

| Vibration requirements | Frequency 5HZ-25HZ, amplitude 3mm, 0.09g; 25HZ-200HZ, amplitude 1.47mm, 116g |

| Protection level | IP67 |

| Cooling method | Natural cooling |

| Weight | 9.8kg |

The system has high efficiency, with an overall maximum efficiency of 93%.

The starting current is small and the torque is large.

Integrated design, compact size, small footprint, easy installation

FOC vector control, high-precision encoder feedback, stable pressure output.

The whole machine is maintenance-free, and no carbon brushes need to be replaced.

The driver and motor have built-in independent temperature alarm thresholds and protection devices.

It can meet the use of harsh working conditions. In addition to the motor output shaft, the protection level is as high as IP67

Equipped with a power contactor pull-in abnormal alarm device.

The output shaft method is optional: (optical shaft flat key,

internal tooth spline and external tooth spline).

Designed by a professional R&D team, providing technical support

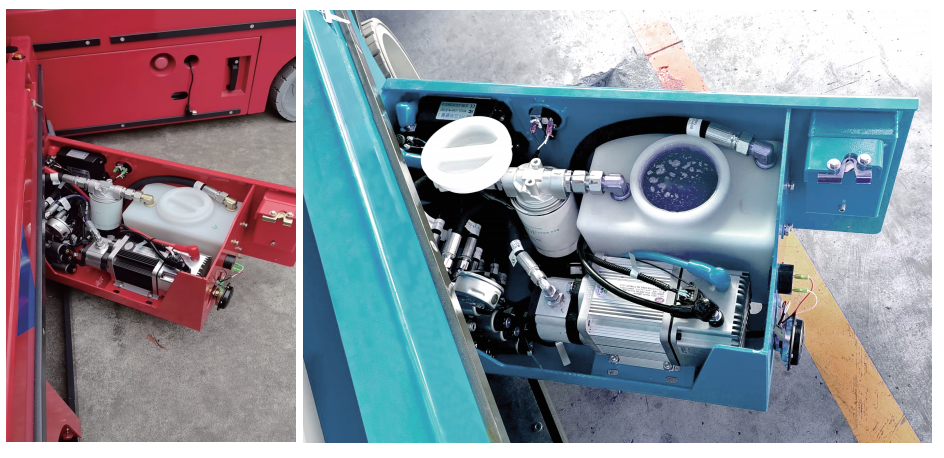

Keya's Integrated Servo Motor can be used in scissor lift work platforms; boom-type aerial vehicles; DC power supply variable frequency hydraulic power units and engineering machinery electric assisted steering; special vehicle travel drives, etc.

This is a picture showing Keya's servo integrated machine installed on Scissor Lift Platforms,

We have reached cooperation with aerial work vehicle companies in many regions such as Europe, South America, Asia, etc. If you are looking for servo system solutions for projects such as scissor lift work platforms; boom-type aerial vehicles; DC power supply variable frequency hydraulic power units and engineering machinery electric assisted steering; special vehicle travel drives, etc., you can contact us for the latest quotation.