Views: 0 Author: Site Editor Publish Time: 2024-11-01 Origin: Site

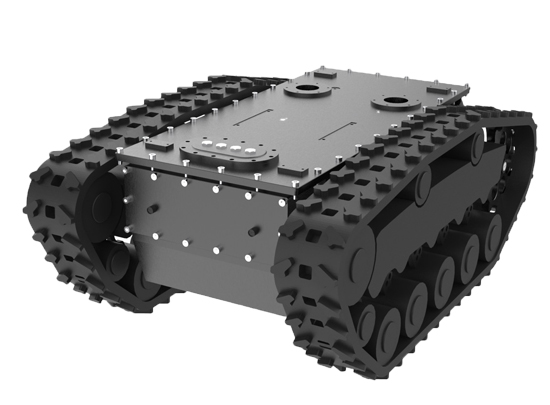

In the rapidly evolving field of robotics, servo motors and servo drives play a crucial role, particularly in specialized applications such as crawler robots. These robots are designed for various demanding environments, including bomb disposal and firefighting, where precision and reliability are paramount. This blog explores the application cases of servo motors and servo drives in explosion-proof crawler chassis and intelligent firefighting robots, highlighting their specifications and advantages.

## Servo Motors and Drives in Explosion-Proof Tracked robot

Low-voltage DC servo motors and drives are extensively utilized in the development of explosion-proof crawler chassis. Keya Electronics has made significant strides in this area by integrating servo motors, drive algorithms, and communication systems tailored to specific customer application scenarios.

### Key Specifications:

- Voltage Range: DC 24V - 96V

- Power Range: 400W - 10KW

- Speed Range: 1500R - 3000R

- Matching Driver: Rated or peak current from 20A to 300A, with options for single or dual drive configurations. The dual drive option notably reduces the required installation space.

### Functional Capabilities:

These systems enable the crawler robots to perform a variety of maneuvers, including:

- Forward and backward movement

- Left and right turns

- In-situ rotation

The integration of advanced control methods allows for precise operation, essential for tasks in hazardous environments.

## Application Case: Bomb detection robot

In bomb disposal scenarios, the use of low-voltage DC servo drives is critical. The parameters for these drives include:

- Modes: Speed mode, position mode, torque mode

- Voltage Range: DC 24V - 96V, suitable for motors rated below 10KW

- Encoder Types: Incremental encoder, absolute encoder, resolver, Hall effect sensors

- Control Methods: CAN2.0, CANopen, RC (model aircraft remote control), RS232, RS485, pulse + direction, 0-5V

### Features:

This series of products employs TI's high-performance DSP as the core control chip, leveraging its superior data processing capabilities. The PMSM full-digital AC servo system utilizes the SVPWM space vector control algorithm, enhancing motor efficiency and responsiveness. The overall system efficiency can reach up to 90%, making it ideal for critical applications like bomb disposal.

## Application Case: Intelligent Firefighting Robots

Servo motors and drives are also pivotal in the development of intelligent firefighting robots. The parameters for low-voltage AC servo motors in this application include:

- Voltage Range: DC 24V - 96V

- Speed Range: 1500R - 3000R

- Rated Power: 0.2KW - 15KW

- Protection Level: IP55 - IP67

- Insulation Level: H

- Feedback Elements: Incremental encoder, absolute encoder, resolver

### Advantages:

- Lower Temperature Rise: Facilitates better heat dissipation design.

- Higher Torque Overload Capacity: Enhances the performance of various mobile robots.

- High Efficiency: Significantly extends battery life.

- Low Speed, High Torque: Reduces wear on the reducer, prolonging its service life.

- Reduced Vibration and Noise: Creates a more comfortable operating environment.

- H-Level Insulation: Extends motor life and ensures excellent overload capacity.

## Conclusion

The integration of servo motors and servo drives in crawler robots, particularly in explosion-proof and firefighting applications, showcases the versatility and efficiency of these technologies. With their advanced features and capabilities, these systems not only enhance operational performance but also ensure safety and reliability in challenging environments. As the robotics industry continues to advance, the role of servo technology will undoubtedly expand, paving the way for more innovative solutions in various sectors.